Innovations Shaping Modern Metal Bending

Introduction to Contemporary Metal Fabrication

Metal fabrication is a core element of industrial manufacturing, supporting sectors such as construction, automotive, machinery, and infrastructure development. As industries evolve, the demand for precise, reliable, and efficient metal forming solutions continues to increase. Modern fabrication methods focus on accuracy, consistency, and reduced material waste, enabling manufacturers to meet strict quality standards while maintaining productivity. Metal bending plays a crucial role in this process, allowing flat sheets to be transformed into functional components used in countless applications. Advancements in technology have significantly improved how bending operations are performed, making them more controlled and efficient.

Importance of Accuracy in Metal Bending Operations

Accuracy is essential in metal bending because even minor deviations can affect the final assembly of a product. Incorrect angles or dimensions may lead to poor fit, structural weakness, or complete rejection of components. Precision bending ensures that parts meet design specifications and perform reliably in their intended applications. Modern bending systems are designed to apply force evenly and consistently. This controlled approach helps maintain material integrity while achieving the desired shape. High accuracy also reduces rework, saving both time and resources.

Understanding the Metal Bending Process

The metal bending process involves applying force to a metal sheet to change its shape without breaking it. This requires careful control of pressure, alignment, and bending speed. Advanced machines allow operators to define precise parameters, ensuring uniform results across repeated production cycles. The press brake is widely used in industrial settings because it offers flexibility and control during bending operations. It allows manufacturers to perform a wide range of bends, from simple angles to complex profiles, using repeatable and accurate methods.

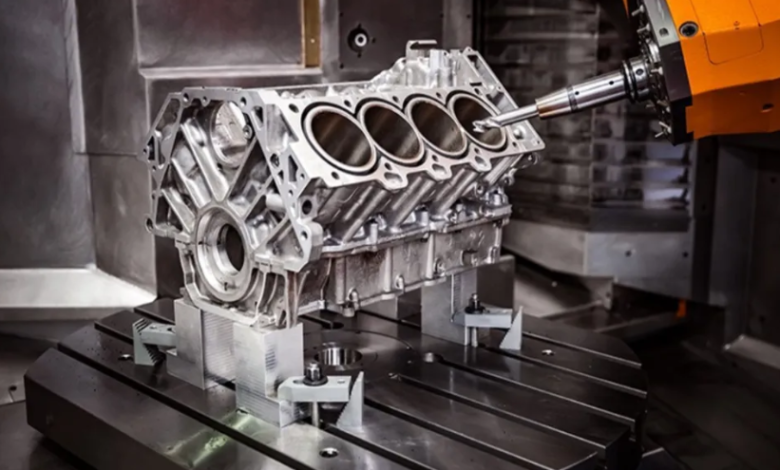

Types of Metal Bending Equipment

Metal bending equipment is available in several configurations, each suited to specific production needs:

- Mechanical bending machines These machines use mechanical force generated by gears and flywheels. They are commonly used for lighter materials and straightforward bending tasks.

- Hydraulic bending machines These systems use fluid pressure to deliver smooth and consistent force, making them suitable for thicker or stronger metals.

- Digitally controlled bending machines These machines incorporate programmable controls, allowing precise adjustment of bending parameters and improved repeatability.

The selection of equipment depends on factors such as material type, production volume, and required precision.

See also: The Essential Role of Technical Documentation Experts

Benefits for Industrial Manufacturing

Modern metal bending technology provides several key advantages for manufacturers:

- Consistent quality: Precise control ensures uniform bends across large production runs.

- Higher efficiency: Automated systems reduce setup time and increase output.

- Material flexibility: Various metals and thicknesses can be processed effectively.

- Reduced waste: Accurate bending minimizes errors and scrap material.

- Operational durability: Robust machine design supports long-term industrial use.

These benefits help manufacturers press brake maintain competitiveness while meeting demanding quality standards.

Choosing the Right Bending Solution

Selecting appropriate bending equipment requires careful evaluation of production requirements. Important considerations include:

- Material properties: Different metals respond differently to bending force and speed.

- Production scale: High-volume facilities require machines capable of continuous operation.

- Precision needs: Industries with tight tolerances require advanced control systems.

- Maintenance requirements: Easy access to servicing reduces downtime and operating costs.

A well-informed decision ensures reliable performance and long-term productivity.

Integration with Modern Manufacturing Systems

Modern manufacturing facilities increasingly rely on integrated production environments. Many bending machines can be connected to automated systems, enabling seamless coordination between design, production, and quality control. This integration allows real-time monitoring of performance, early detection of maintenance needs, and improved workflow efficiency. Data-driven insights help manufacturers optimize operations and reduce unplanned downtime.

Safety in Metal Bending Operations

Safety is a critical priority in industrial environments. Modern bending equipment includes features such as emergency stop mechanisms, protective guards, and overload protection systems. These features help prevent accidents and protect operators during daily operations. In addition to machine safety features, proper training is essential. Skilled operators understand safe operating procedures and can respond effectively to unexpected situations.

Energy Efficiency and Environmental Considerations

Energy efficiency has become an important focus in manufacturing. Modern bending machines are designed to optimize energy use by applying force only when necessary. Improved control systems help reduce power consumption while maintaining performance. By adopting energy-efficient equipment, manufacturers can lower operational costs and reduce environmental impact, supporting sustainable production practices.

Role of Skilled Operators in Modern Fabrication

Despite advances in automation, skilled operators remain essential in metal bending operations. Proper training enables operators to program machines accurately, monitor performance, and troubleshoot issues efficiently. Experienced personnel can fine-tune bending processes to improve quality and consistency. Continuous training also ensures that operators stay updated with new technologies and industry standards.

Future Trends in Metal Bending Technology

The future of metal bending technology is expected to focus on increased automation and intelligent control systems. Artificial intelligence and data analysis may allow machines to adjust bending parameters automatically based on material behavior and production history. These innovations will further improve accuracy, efficiency, and adaptability, enabling manufacturers to handle increasingly complex designs and production demands.

Conclusion

Metal bending technology has evolved significantly, offering manufacturers improved precision, efficiency, and reliability. Modern equipment supports consistent production, reduced waste, and enhanced safety. The press brake remains a fundamental tool in industrial fabrication, supporting a wide range of applications. By understanding current capabilities and future trends, manufacturers can make informed decisions that contribute to long-term success.