ABB Motors and Mechanical Parts: Essential Guide for Industrial Applications

Introduction to ABB Motors and Mechanical Parts

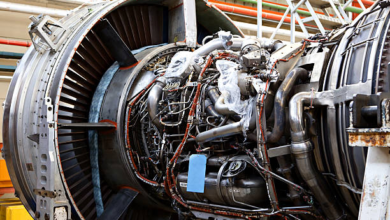

ABB motors and mechanical parts are fundamental components in modern industrial systems. These products are designed to deliver reliable performance, energy efficiency, and long operational life across various applications. From manufacturing lines to heavy machinery, ABB motors and mechanical parts provide the backbone of industrial operations, ensuring that machines function smoothly and efficiently.

The Role of ABB Motors and Mechanical Parts in Industry

ABB motors and mechanical parts serve multiple purposes in industrial setups. They not only power machines but also ensure precise control, smooth operation, and reduced wear and tear. Their importance extends to several areas:

- Power Transmission: Mechanical parts, including couplings, shafts, and gears, work in tandem with motors to transmit energy efficiently.

- Reliability: High-quality ABB motors minimize downtime and prevent operational delays.

- Performance Optimization: Combined systems of motors and mechanical parts improve machine efficiency and productivity.

- Customization: ABB provides solutions tailored to specific industrial requirements, from torque and speed to environmental adaptability.

Selecting ABB motors and mechanical parts ensures that industries maintain consistent operations while reducing maintenance costs and energy consumption.

Types of ABB Motors Offered

ABB motors are available in multiple types to meet diverse industrial needs:

Low Voltage Motors

These motors are used in applications such as pumps, fans, compressors, and smaller machinery. They provide reliability and energy efficiency for continuous operation.

Medium Voltage Motors

Medium voltage motors are suitable for high-power industrial machinery. They are often used in processing plants, mining, and water treatment systems.

DC Motors

DC motors offer precise control over speed and torque, making them ideal for conveyors, cranes, and robotic systems.

Synchronous Motors

Synchronous motors maintain constant speed even under varying loads. They are critical in processes requiring stable operation, such as generators and precision equipment.

Induction Motors

Induction motors are robust and durable, commonly used in heavy-duty industrial machinery due to their low maintenance and long life.

See also: Role of small oled display manufacturers in Modern Technology

Key Mechanical Parts by ABB

ABB also provides mechanical components that complement their motors and enhance industrial machinery performance:

- Couplings: Ensure smooth power transfer between motor and driven equipment.

- Gearboxes: Modify speed and torque to match operational requirements.

- Bearings: Support rotating elements, reducing friction and wear.

- Shafts and Mountings: Provide alignment and stability for motor-driven machinery.

- Protective Covers and Enclosures: Enhance safety and protect components from dust, moisture, and other environmental hazards.

These mechanical parts, when paired with ABB motors, provide a complete and reliable system for industrial operations.

Applications of ABB Motors and Mechanical Parts

ABB motors and mechanical parts find applications across various industries:

Manufacturing

Used in production lines, CNC machines, presses, and automated assembly lines. ABB motors ensure consistent motion, while mechanical parts optimize energy transmission.

Water and Wastewater Management

Motors power pumps, blowers, and aerators, while mechanical components ensure efficient torque transmission and durability in harsh environments.

HVAC Systems

Motors drive fans and compressors, and mechanical parts like shafts and couplings maintain alignment and reduce vibration.

Mining and Heavy Industry

Motors and mechanical components handle demanding conditions, powering crushers, mills, and conveyors with high reliability and minimal maintenance.

Food and Beverage Industry

Precision motors and sanitary mechanical parts ensure compliance with hygiene standards while maintaining high efficiency in processing and packaging equipment.

Advantages of Choosing ABB Motors and Mechanical Parts

Selecting ABB motors and mechanical parts provides numerous benefits:

- High Performance: Designed for efficiency, long life, and reliability.

- Reduced Downtime: Durable components decrease the risk of failure and maintenance interruptions.

- Energy Efficiency: Advanced motor designs and optimized mechanical components lower operational costs.

- Custom Solutions: ABB offers tailored systems to meet specific operational and environmental requirements.

- Technical Support: ABB provides comprehensive guidance, from installation to maintenance and troubleshooting.

These advantages make ABB motors and mechanical parts a preferred choice for industrial operators seeking quality and efficiency.

Factors to Consider When Selecting ABB Motors and Mechanical Parts

When choosing ABB motors and mechanical parts, several factors should be considered:

- Application Requirements: Determine power, torque, speed, and load conditions.

- Environment: Evaluate temperature, humidity, dust, and chemical exposure.

- Efficiency Needs: Consider energy-efficient options to reduce long-term operational costs.

- Maintenance Availability: Check accessibility for inspection, repair, and replacement.

- Customization Needs: Identify if special mechanical configurations are required for your operation.

These considerations ensure optimal performance and longevity of the motor and mechanical system.

Future Trends in ABB Motor and Mechanical Parts Industry

The industrial motor and mechanical parts industry continues to evolve, with new trends shaping product development:

- Energy Efficiency: Increased focus on reducing power consumption without compromising performance.

- Digital Integration: Motors with IoT and sensor technologies enable predictive maintenance and real-time monitoring.

- Sustainability: Use of eco-friendly materials and manufacturing processes is gaining priority.

- Advanced Materials: Lightweight and durable materials improve performance and reduce wear.

- Automation: Integration with automated production systems improves precision and operational efficiency.

Staying aware of these trends allows industries to adopt advanced solutions and maintain competitive advantage.

Conclusion

ABB motors and mechanical parts are essential for reliable, efficient, and durable industrial operations. From low and medium voltage motors to precise DC and synchronous motors, ABB provides a complete range of solutions for varied industrial needs. When combined with high-quality mechanical parts such as couplings, gearboxes, and bearings, ABB products ensure smooth operation, reduced downtime, and improved productivity.

Choosing ABB motors and mechanical parts guarantees performance, energy efficiency, and long-term operational success, making them a vital investment for industries worldwide.