Choosing the Right Gas and Steam Turbine Repair Company: What You Need to Know

Gas and steam turbines are critical assets in power plants, industrial facilities, and cogeneration systems. Their performance, reliability, and operational efficiency directly impact energy output, plant economics, and overall productivity. Over time, these turbines experience wear and tear, mechanical stress, and thermal fatigue, making periodic maintenance and repair essential. However, choosing the right gas turbine repair company provider can be a complex decision for plant managers and engineers.

This guide explores key considerations when selecting turbine repair providers, including certifications, turnaround times, cost comparisons between repair and replacement, service reliability, and the value of specialized technicians. By the end, you’ll understand why partnering with experienced gas turbine maintenance companies can ensure operational efficiency, minimize downtime, and extend turbine lifespan.

Understanding Gas and Steam Turbine Repairs

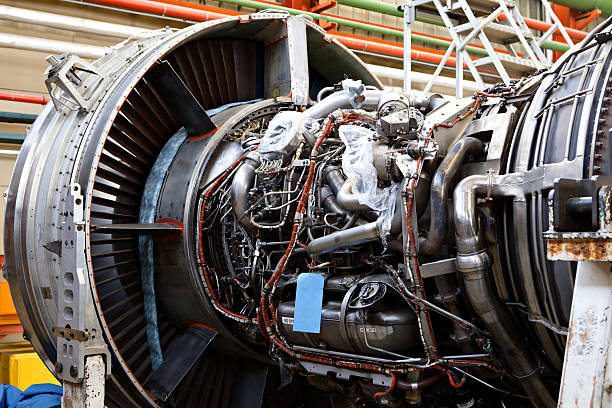

Before diving into provider selection, it’s essential to understand what turbine repair entails. Gas and steam turbines operate under extreme conditions: high temperatures, rapid rotational speeds, and continuous pressure cycles. Components such as rotors, blades, combustion chambers, bearings, and control systems can degrade over time.

Common repair and maintenance services include:

- Rotor and blade repair: Rebalancing, resurfacing, or replacing worn blades and rotors.

- Combustion system maintenance: Cleaning, inspection, and replacement of combustion liners and fuel nozzles.

- Bearing and lubrication services: Preventing excessive wear and ensuring smooth operation.

- Vibration analysis and balancing: Detecting imbalances early to prevent catastrophic failure.

- Control system calibration: Ensuring operational safety and efficiency.

Choosing a qualified repair company ensures these services are performed accurately, preventing minor issues from becoming costly failures.

Why Selecting the Right Repair Company Matters

The choice of a turbine repair provider can significantly affect operational uptime, repair quality, and long-term costs. Key factors include:

1. Reliability and Expertise

A trusted gas turbine repair company brings decades of technical experience, specialized knowledge, and proven repair procedures. Experienced technicians are trained to:

- Diagnose issues accurately using advanced diagnostic tools

- Execute repairs adhering to manufacturer specifications

- Minimize downtime with efficient scheduling and execution

Choosing an inexperienced provider may result in incomplete repairs, extended outages, or repeated maintenance, increasing total costs.

2. Certification and Compliance

Certified service providers demonstrate adherence to industry standards, safety regulations, and quality control protocols. Key certifications to look for include:

- ISO 9001 (Quality Management Systems)

- ASME or API certifications relevant to turbine maintenance

- OEM-approved repair qualifications

A certified company ensures compliance with safety and environmental regulations while maintaining turbine reliability and performance.

3. Turnaround Times

Downtime is one of the most costly aspects of turbine maintenance. Reliable repair companies provide clear timelines, rapid response, and the ability to handle urgent repairs.

- Standard repairs: Rotor rewinds, blade replacements, and minor overhauls often have turnaround times ranging from a few days to several weeks, depending on turbine size and complexity.

- Emergency repairs: Some providers offer fast-track services to restore operation in critical outages.

Choosing a company that balances speed with quality ensures minimal production loss and maximizes operational efficiency.

See also: The Essential Role of Technical Documentation Experts

Comparing Repair vs. Replacement Costs

When a turbine experiences significant wear, managers face the decision: repair or replace. While new turbines can provide long-term benefits, they come with higher capital expenditure, extended lead times, and installation challenges.

Repair Advantages:

- Lower upfront cost: Repairing worn components is typically 30–50% of replacement cost.

- Shorter downtime: Repairs can often be completed in days or weeks, whereas new units may require months.

- Extended life of existing assets: Well-executed repairs restore performance, extending the turbine’s operational lifespan.

- Reduced logistical challenges: No need for complete installation, alignment, or retrofitting.

Replacement Considerations:

- Higher capital investment: Full replacement costs can be substantial.

- Extended downtime: Manufacturing, shipping, and installation can take months.

- Potential for modernization benefits: New turbines may improve efficiency and reduce emissions.

Ultimately, a reliable repair company will help assess the turbine’s condition, cost implications, and risk factors, allowing informed decisions between repair and replacement.

Evaluating Service Quality

Selecting the right turbine repair company goes beyond cost and certifications. Consider service quality, including:

1. Case Studies and Track Record

Reviewing past projects demonstrates a company’s capability to handle turbines similar to yours. Examples may include:

- Successful rotor rewinds on industrial gas turbines

- Blade refurbishments on high-capacity steam turbines

- Emergency repairs completed within tight deadlines

A proven track record indicates expertise, reliability, and consistent results.

2. Availability of Specialized Technicians

Gas and steam turbines require highly skilled technicians with specialized training in areas such as:

- High-speed rotor balancing

- Combustion chamber inspections

- Vibration diagnostics

- Control system calibration

Companies with dedicated experts ensure precise repairs, reducing the risk of operational failures and extending turbine life.

3. Equipment and Technology

Modern repair companies use advanced equipment for diagnostics, repair, and testing. Examples include:

- Laser alignment tools

- High-speed balancing machines

- Vibration monitoring systems

- Thermal imaging and NDT (Non-Destructive Testing)

Advanced technology ensures accurate repairs, faster turnaround, and long-lasting performance improvements.

Case Study: Effective Turbine Repair

Consider a power plant experiencing reduced efficiency in a gas turbine due to blade erosion and rotor imbalance. Partnering with a specialized gas turbine repair company allowed the plant to:

- Conduct detailed diagnostics and vibration analysis

- Replace and balance worn blades

- Calibrate the control system for optimal operation

As a result, the turbine’s output efficiency increased, fuel consumption decreased, and the plant avoided costly downtime and the need for full replacement.

This example demonstrates the value of working with experienced gas turbine maintenance companies that combine technical expertise, certified procedures, and rapid turnaround.

Additional Considerations

When selecting a turbine repair provider, also evaluate:

- Geographic proximity: Shorter travel distances for technicians can reduce downtime and logistical challenges.

- Flexibility: Ability to handle scheduled and emergency maintenance.

- Transparent reporting: Detailed inspection reports, repair documentation, and recommendations for ongoing maintenance.

- Long-term partnership potential: Consistent service relationships enable predictive maintenance planning and lifecycle management.

These factors ensure the provider not only addresses current issues but also supports long-term turbine reliability and plant performance.

Why Allied Power Group Stands Out

Allied Power Group is a leading provider of steam turbine repair services, and comprehensive maintenance solutions. Key advantages include:

- Certified technicians with extensive experience across industrial and utility turbines

- Rapid turnaround for emergency and scheduled repairs

- Advanced diagnostic and balancing equipment for precise, reliable repairs

- Proven track record of restoring turbine performance and extending operational life

- Full-service support for inspection, repair, and lifecycle maintenance planning

Partnering with Allied Power Group ensures turbines operate efficiently, safely, and reliably, minimizing downtime and maximizing return on investment.

For inquiries and service consultations, power plant operators can contact us to discuss customized turbine maintenance and repair solutions.

Conclusion

Choosing the right gas and steam turbine repair company is a strategic decision with far-reaching implications for plant performance, efficiency, and cost management. Key considerations include:

- Reliability, expertise, and proven track record

- Certifications and compliance with industry standards

- Turnaround times and emergency repair capabilities

- Cost comparison between repair and replacement

- Specialized technicians and advanced repair technology

Working with experienced gas turbine maintenance companies and gas turbine repair companies like Allied Power Group ensures high-quality, reliable service, minimized downtime, and extended turbine lifespan.

Regular maintenance, expert repairs, and strategic planning are essential for maximizing operational efficiency, reducing costs, and protecting critical power generation assets.