Choosing the Right Custom Washers for Industrial Applications

Introduction to Custom Washers

Custom washers are specialized components designed to meet unique industrial requirements. Unlike standard washers, these components can be tailored in size, material, and shape to suit specific machinery, assemblies, and applications. Working with a reputable provider ensures that every washer meets strict quality standards and delivers consistent performance.

Types of Custom Washers

Flat Custom Washers

Flat custom washers provide even load distribution across surfaces. They are ideal for assemblies where uniform pressure is essential to prevent damage to components or surfaces. Customized flat washers can vary in diameter, thickness, and material depending on the application.

Lock Custom Washers

Lock washers prevent loosening caused by vibrations or dynamic loads. Custom designs, such as split rings, external tooth, and conical washers, are tailored to specific requirements, ensuring stability in machinery and assemblies.

Specialty Custom Washers

Industries may require washers with special properties, such as insulating, sealing, or spacer washers. These custom washers are engineered to address unique challenges, such as electrical insulation, high-temperature resistance, or corrosion protection.

Materials Used for Custom Washers

Custom washers can be produced from a wide range of materials to meet performance requirements:

- Stainless steel for corrosion resistance

- Carbon steel for strength

- Brass and copper for electrical conductivity

- Nylon and other plastics for lightweight or insulating applications

The choice of material impacts durability, functionality, and the overall performance of the component in specific industrial environments.

Applications of Custom Washers

Automotive Industry

Custom washers play a critical role in automotive assemblies, including engines, suspensions, and body fittings. Precision in design ensures that load is distributed evenly, connections remain secure, and the components operate safely under dynamic conditions.

Electronics and Electrical Systems

Custom washers are used in electronics for insulation, spacing, and load distribution. Properly designed washers prevent electrical shorts, protect delicate components, and maintain consistent performance in devices and equipment.

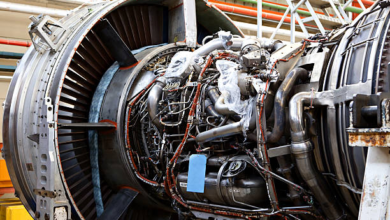

Industrial Machinery

Heavy machinery relies on custom washers to reduce wear, distribute pressure, and secure fasteners. High-quality washers contribute to operational efficiency, reduce maintenance requirements, and extend the life of equipment.

See also: Ignite Your Social Media with Fresh and Interactive Techniques

Choosing a Reliable Custom Washers Supplier

Production Capabilities

Selecting a reliable supplier requires evaluating custom washers their equipment, technology, and production capacity. Advanced stamping presses, CNC machines, and skilled technicians ensure precision manufacturing of custom washers according to detailed specifications.

Quality Assurance

Reputable suppliers implement strict quality control measures, including material verification, dimensional inspections, and defect monitoring. Certifications like ISO 9001 confirm adherence to international quality standards and ensure consistent product quality.

Design and Engineering Support

A capable custom washers provider offers engineering support to optimize designs for manufacturing. This includes material recommendations, die design guidance, and process improvements to reduce costs and enhance performance.

Benefits of Custom Washers

Enhanced Performance

Custom washers are designed to meet specific application requirements. This ensures optimal performance, reduces the risk of mechanical failure, and improves overall system reliability.

Cost Efficiency

Although custom washers may involve higher initial costs, their precision and suitability reduce maintenance and replacement expenses. Long-term savings are achieved through increased component life and minimized downtime.

Versatility

The ability to produce washers in various sizes, shapes, and materials allows manufacturers to meet diverse industrial needs, ranging from automotive to electronics, aerospace, and machinery applications.

Innovations in Custom Washers Production

Modern manufacturing has introduced innovations that improve custom washers production:

- CNC precision stamping for high accuracy

- Robotic automation for faster production

- Advanced materials for lightweight and durable washers

These innovations enable the creation of high-quality washers tailored to the evolving needs of different industries.

Sustainability in Washers Manufacturing

Leading manufacturers adopt eco-friendly practices such as recycling scrap materials, minimizing energy consumption, and reducing waste. Sustainable production not only benefits the environment but also contributes to cost efficiency and compliance with regulatory standards.

Conclusion

Custom washers are essential components in modern industrial assemblies, providing precision, durability, and reliability. Selecting the right supplier ensures quality production, design support, and timely delivery. By partnering with a skilled custom washers manufacturer, businesses can achieve operational efficiency, reduce costs, and enhance the performance of their equipment and assemblies.