Advancing Safety Measures in Modern Industries

Maintaining operational safety and efficiency in modern industries has become increasingly challenging. With complex machinery, intricate electrical systems, and high-demand production lines, identifying potential problems before they escalate is essential. One key innovation that has transformed industrial inspections is thermal imaging technology, which provides accurate and rapid analysis of heat patterns to prevent hazards.

Understanding Thermal Imaging in Industrial Applications

Thermal imaging allows professionals to visualize temperature variations in equipment and infrastructure. By detecting infrared radiation, these devices highlight areas where excessive heat may indicate malfunction, wear, or energy inefficiency.

Using a thermal inspection camera, maintenance teams can perform inspections without direct contact with equipment, making it safer and faster than traditional methods. This technology has applications across multiple industries, including manufacturing, construction, electrical systems, and energy management.

Advantages of Thermal Inspections

Implementing thermal inspection technology provides numerous benefits:

- Early Detection of Issues: Thermal anomalies often precede visible damage, allowing proactive intervention.

- Increased Safety: Non-contact inspections reduce exposure to high temperatures, electricity, or confined spaces.

- Operational Efficiency: Quick identification of hotspots helps prioritize maintenance tasks, minimizing downtime.

- Energy Optimization: Detecting heat loss in equipment or infrastructure can lead to significant energy savings.

- Versatility: Devices can be used for mechanical, electrical, and building system inspections.

See also: How Everyday Technology Improves Pet Safety

How Thermal Inspection Cameras Function

A thermal inspection camera works by capturing infrared radiation emitted from surfaces. This data is then converted into a visual format, commonly known as a thermal image or heat map.

- Infrared Sensors: Capture precise temperature measurements from objects without physical contact.

- Color Visualization: Thermal images often use color gradients to indicate temperature differences, with warmer areas appearing in shades of red or yellow and cooler regions in blue or green.

- Analysis Tools: Many cameras include software for recording, analyzing, and reporting temperature variations over time.

This combination of hardware and software ensures accurate detection of potential failures and supports decision-making for preventive maintenance.

Common Industrial Applications

Thermal inspection cameras are widely utilized across industries for several key applications:

- Electrical Systems: Detecting overheating components, loose connections, or circuit overloads to prevent electrical fires and malfunctions.

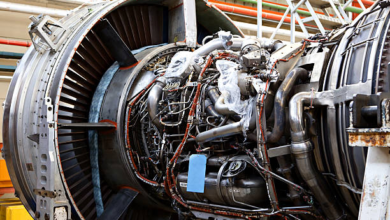

- Mechanical Equipment: Monitoring motors, bearings, and other moving parts for excessive friction or wear.

- Building and Construction: Assessing insulation performance, identifying leaks, and monitoring HVAC systems.

- Energy Management: Pinpointing energy loss and inefficiencies in industrial machinery and infrastructure.

- Quality Control: Ensuring that heat-sensitive processes in manufacturing meet required standards.

Choosing the Right Thermal Inspection Camera

Selecting an appropriate device is crucial for accurate inspections. Key factors to consider include:

- Resolution: Higher resolution provides more detailed images for precise analysis.

- Temperature Range: Choose a camera capable of measuring the expected extremes in your operational environment.

- Portability: Handheld, lightweight models allow quick inspections across multiple sites.

- Data Management: Devices with built-in storage and reporting features simplify documentation and analysis.

- Durability: Industrial-grade cameras must withstand dust, moisture, and occasional impacts.

Benefits Beyond Safety and Maintenance

Thermal imaging technology is not only useful for immediate safety concerns. Organizations can leverage these tools to:

- Reduce Downtime: By detecting issues early, companies can schedule maintenance before failures disrupt operations.

- Optimize Costs: Efficient monitoring minimizes repair expenses and reduces energy consumption.

- Ensure Compliance: Thermal inspections provide documentation for safety and industry regulatory requirements.

- Enhance Worker Safety: Non-contact inspections reduce the risk of injuries associated with direct equipment handling or hazardous environments.

Emerging Trends in Thermal Technology

The thermal inspection industry is constantly evolving with new trends enhancing usability and efficiency:

- IoT Integration: Real-time monitoring and automated alerts from connected devices improve responsiveness.

- AI-Powered Analysis: Machine learning algorithms help detect patterns, predict equipment failures, and prioritize maintenance tasks.

- Miniaturization: Compact, lightweight cameras increase mobility and ease of use.

- Improved Imaging: Advances in sensor technology offer higher resolution, sharper thermal images, and better accuracy.

Practical Tips for Effective Inspections

For organizations using thermal inspection cameras, following best practices ensures reliable results:

- Conduct inspections under consistent environmental conditions to minimize false readings.

- Regularly calibrate devices to maintain accuracy.

- Combine thermal data with visual inspections to confirm anomalies.

- Maintain detailed records for trend analysis and preventive planning.

Conclusion

As industries grow more complex, ensuring safety, efficiency, and regulatory compliance requires advanced tools. Thermal inspection cameras offer a reliable solution for identifying potential problems, optimizing energy use, and protecting personnel. By adopting this technology, businesses can prevent costly equipment failures, maintain operational continuity, and create safer workplaces.

The integration of modern thermal imaging devices represents a strategic investment for industries seeking long-term efficiency and risk mitigation. With the right device, proper training, and systematic application, companies can leverage this technology to enhance their maintenance programs and secure a competitive edge.